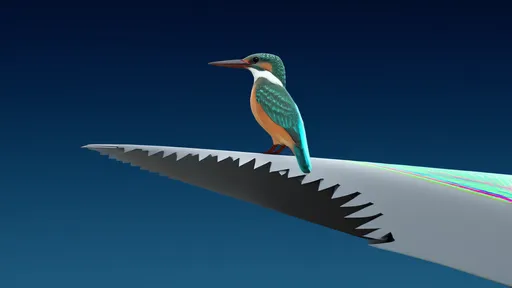

The natural world has long served as a source of inspiration for engineering solutions, and the latest innovation in wind energy is no exception. Researchers have turned to the humble kingfisher, a bird renowned for its near-silent dive into water, to address one of the most persistent challenges in wind turbine technology: aerodynamic noise. The unique beak shape of the kingfisher, which allows it to enter water with minimal splash and noise, has provided critical insights for redesigning wind turbine blades to operate more quietly without sacrificing efficiency.

Wind turbines are a cornerstone of renewable energy, but their noise emissions have been a significant barrier to widespread adoption, particularly in populated areas. Traditional blade designs generate substantial noise as they slice through the air, primarily due to turbulent airflow at the trailing edge. This noise not only affects community acceptance but can also lead to regulatory hurdles. By mimicking the kingfisher’s beak, engineers have developed blade profiles that significantly reduce this turbulence, resulting in quieter operation.

The Science Behind the Silence

The kingfisher’s beak is a marvel of natural engineering. Its elongated, tapered shape minimizes the disruption of air and water as the bird dives, effectively reducing the pressure waves that cause noise. This principle, known as biomimicry, has been applied to wind turbine blades with remarkable success. Computational fluid dynamics (CFD) simulations and wind tunnel tests have shown that blades with a serrated or uneven trailing edge, inspired by the beak’s structure, can cut noise levels by up to 10 decibels—a reduction comparable to the difference between a busy street and a quiet conversation.

Beyond noise reduction, the biomimetic design also enhances aerodynamic efficiency. The smoother airflow around the modified blades reduces drag, allowing turbines to capture more energy from the wind at lower rotational speeds. This dual benefit of quieter and more efficient operation could revolutionize the wind energy industry, making turbines more viable in noise-sensitive environments such as urban fringes and ecologically protected areas.

From Concept to Commercialization

The journey from biological observation to industrial application has involved extensive collaboration between biologists, engineers, and material scientists. Early prototypes faced challenges in balancing noise reduction with structural integrity, as the serrated edges had to withstand the immense forces exerted by high winds. Advanced composite materials, similar to those used in aerospace engineering, have been employed to ensure durability without adding excessive weight.

Field tests in Europe and North America have demonstrated the real-world potential of these designs. One pilot project in Germany reported a 30% reduction in noise complaints from nearby residents after retrofitting turbines with kingfisher-inspired blades. Meanwhile, manufacturers are exploring scalable production methods to bring these blades to market without significantly increasing costs. 3D printing and modular blade assembly are among the techniques being investigated to achieve this goal.

Implications for the Future of Wind Energy

The adoption of kingfisher-inspired blade designs could mark a turning point for wind energy. As governments worldwide push for higher renewable energy targets, addressing the social and environmental impacts of wind farms becomes increasingly critical. Quieter turbines could expand the potential sites for wind energy projects, bringing clean power closer to demand centers and reducing reliance on long-distance transmission lines.

Moreover, this innovation underscores the value of interdisciplinary research. By bridging biology and engineering, scientists have unlocked a solution that neither field could have achieved alone. The success of this approach may inspire further biomimetic applications in renewable energy, from solar panels modeled after leaf structures to wave energy converters shaped like fish.

As the technology matures, the next challenge will be integrating these advanced blades into existing wind farms and ensuring compatibility with next-generation turbine designs. With continued refinement, the kingfisher’s silent dive may soon symbolize not just nature’s elegance, but humanity’s ability to harness it for a sustainable future.

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025

By /Aug 12, 2025