In the burgeoning market of pet technology, the automated pet feeder has emerged as a cornerstone product for owners seeking convenience and consistency in their pet care routines. These devices promise to dispense precise portions of food at scheduled times, ensuring pets are fed even when their humans are away. However, the core value proposition of these gadgets hinges on two critical, and often intertwined, performance metrics: portion accuracy and operational reliability. A feeder that delivers inconsistent amounts or, worse, fails entirely, transforms from a helpful assistant into a source of anxiety and potential health risks for the animal. This report delves into the current landscape of smart pet feeders, examining the technological underpinnings that dictate their precision and the common failure points that challenge their dependability.

The principle behind a smart feeder's dispensing mechanism seems deceptively simple: a motor rotates an auger or opens a trapdoor to release a predetermined quantity of kibble. Yet, achieving true precision is a complex engineering challenge. The most significant variable is the food itself. Kibble size, shape, density, and even oiliness can drastically affect how it flows through the mechanism. A feeder calibrated for small, uniform, dry round kibble will likely struggle with large, irregularly shaped, or greasy pieces. This is the primary culprit behind portion inaccuracies. A device programmed to dispense a quarter cup might, in reality, deliver anything from a scant eighth to an overflowing half-cup over successive cycles. This inconsistency is not merely an inconvenience; for pets on strict veterinary diets, diabetics requiring precise insulin-timing correlations, or animals prone to obesity, these fluctuations can have serious health consequences.

Manufacturers employ various strategies to combat this inherent variability. High-end models often incorporate load cells or optical sensors. A load cell, essentially a tiny scale placed under the food bowl, weighs the dispensed food in real-time. The feeder's control system will continue the dispensing cycle until the target weight is achieved, compensating for kibble variations. This method is generally considered the gold standard for accuracy. Optical sensors work by counting pieces of kibble as they pass through a beam of light. While effective for very uniform food, this method can be fooled by dust, irregular shapes, or pieces sticking together. The sophistication of this feedback loop—the sensor technology and the processing algorithm—is a key differentiator between a premium product and a budget model, and it is directly reflected in the unit's price.

Beyond the food type, mechanical design plays a paramount role. The geometry of the food hopper and the exit chute is critical to prevent bridging—a phenomenon where pieces of kibble interlock, creating an arch that prevents further food from falling—and clogging. Auger-based systems, which use a corkscrew-like mechanism to push food out, are generally robust but can crush brittle kibble, creating dust that then gums up the works. Trapdoor or paddle systems are simpler but can be less consistent. The quality of the motor is another vital factor; a weak or poorly calibrated motor may not have the torque to overcome a minor jam or may stutter, leading to inaccurate rotations and thus, inaccurate portions. The relentless pursuit of quieter operation has also led some manufacturers to use less powerful motors, which can trade silence for reliability when faced with a challenging food type.

While accuracy concerns what comes out, reliability concerns whether anything comes out at all. The failure rate of these devices is a significant concern for consumers, as a malfunction can leave a pet without food for an extended period. The most common point of failure is the motor itself. These small DC motors are subject to wear and tear, and a sustained jam can overheat and burn them out. Power supply issues are another frequent culprit. Many feeders rely on a low-voltage DC adapter, and power surges or brownouts can fry the internal circuitry. As a countermeasure, most reputable models include a battery backup system, typically using D-cell batteries, to maintain operation during a power outage. However, the effectiveness of this backup is wholly dependent on the user maintaining fresh batteries, a step that is often overlooked.

Connectivity, a hallmark of the "smart" label, introduces its own unique set of reliability challenges. These feeders rely on a stable Wi-Fi connection to receive commands from the owner's smartphone app. A dropped internet connection on either end can lead to missed meals, even if the feeder itself is mechanically sound. App glitches, server outages on the manufacturer's side, and Bluetooth pairing issues further complicate the ecosystem. For a device performing such a fundamental care task, this dependence on a complex digital infrastructure represents a single point of failure that is entirely outside the user's control. A poorly designed app with a confusing interface can also lead to user error, such as accidentally disabling schedules, which is often misreported as a device failure.

Consumer reviews and product return data paint a vivid picture of the market's reliability distribution. There is a clear correlation between price point and reported failure rates. Budget feeders, often retailing for under fifty dollars, are frequently cited in reviews for motor failures, jamming issues, and catastrophic electronic faults within the first few months of use. Their plastic components are often thinner, their motors less robust, and their software barely tested. Mid-range models show improved performance, but can still suffer from inconsistent accuracy, especially with non-standard food. The premium segment, featuring brands with established reputations in pet tech or consumer electronics, generally boasts significantly lower failure rates and more sophisticated accuracy-correction systems. However, they are not immune to problems, often facing more complex software-related issues instead of simple mechanical failures.

The user's role in the system's reliability cannot be understated. Proper maintenance is the most effective way to prevent the majority of common failures. This includes regular and thorough cleaning of the hopper, auger, and bowl to remove dust and grease buildup, which is the primary cause of jams and motor strain. Using only the recommended kibble type and size is crucial for maintaining accuracy. Ensuring a stable power connection and regularly replacing backup batteries are simple steps that prevent a huge category of power-related failures. Unfortunately, many consumers purchase these devices under the assumption that they are "set it and forget it" appliances, leading to neglect that inevitably results in a malfunction that is blamed on the product rather than the upkeep.

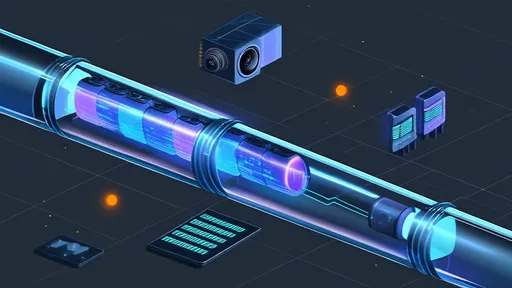

Looking forward, the industry is trending towards greater integration and intelligence to solve these core issues. The next generation of feeders is beginning to incorporate more advanced machine learning algorithms. These systems can learn the flow characteristics of the specific food being used over time, self-adjusting the motor's run time to achieve more consistent portion sizes regardless of kibble variability. We are also seeing the emergence of built-in cameras not just for monitoring, but for computer vision tasks. A camera could theoretically monitor the bowl, identify a portion that is too small or too large, and trigger a corrective secondary dispense or alert the owner. For reliability, diagnostics are becoming more robust. Feeders can now self-test their motors and sensors, and send pre-emptive alerts to an owner's phone warning of a potential jam or motor strain before a total failure occurs, turning a reactive problem into a manageable notification.

In conclusion, the smart pet feeder market is a tale of two performance indicators locked in a constant struggle against physics and entropy. Dispensing accuracy is a nuanced battle against the infinite variability of dry pet food, won through sophisticated sensing and feedback technology. Operational reliability is a war on multiple fronts—against mechanical wear, electrical fragility, and digital instability. While premium models have made significant strides in mitigating these issues, they remain an inherent challenge of the product category. For the consumer, the choice involves a careful calculation: weighing the undeniable convenience against the potential risks, and understanding that the device's performance is not solely a function of its engineering, but also a product of diligent owner maintenance and the unpredictable nature of the modern connected home.

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025